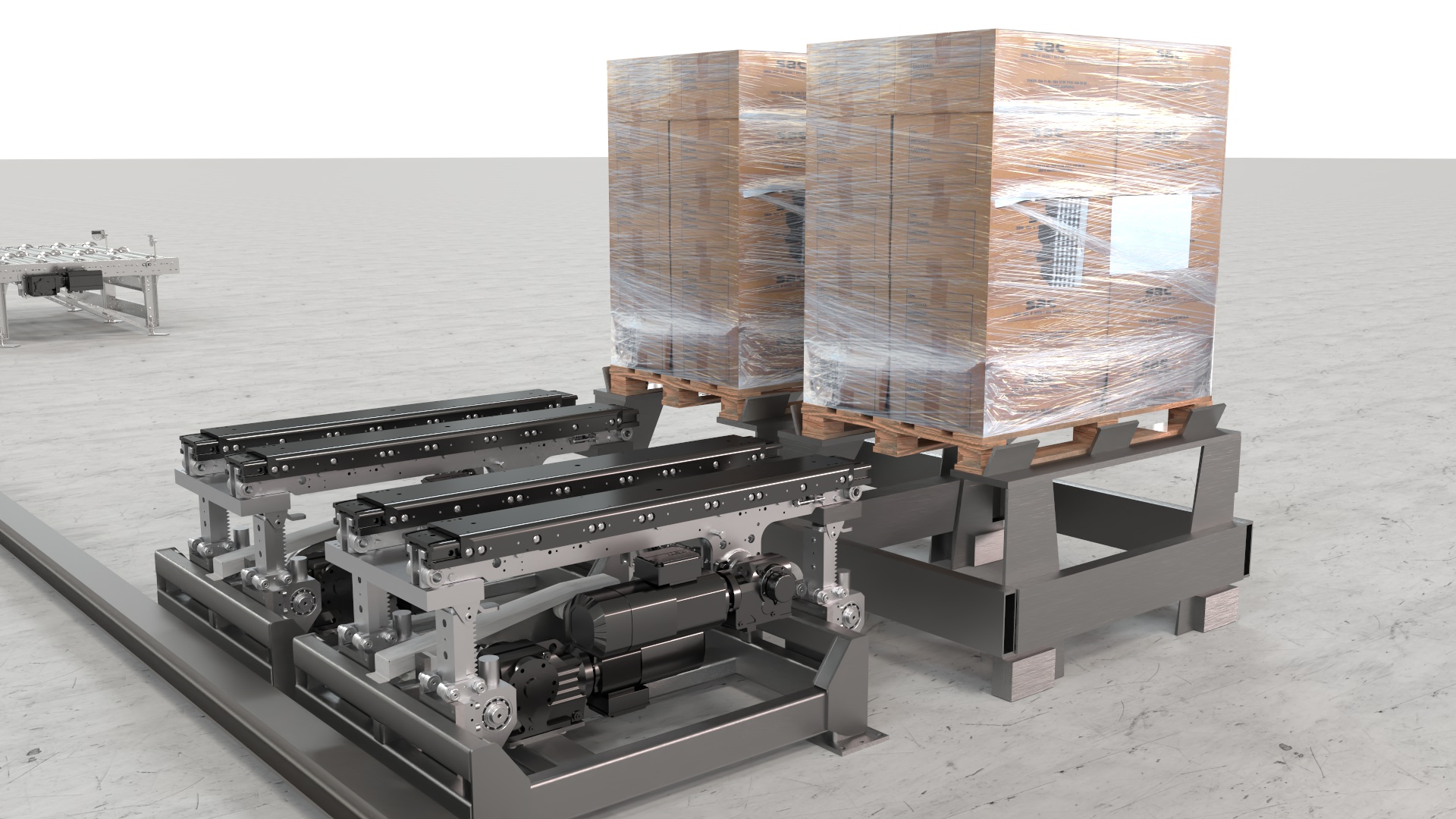

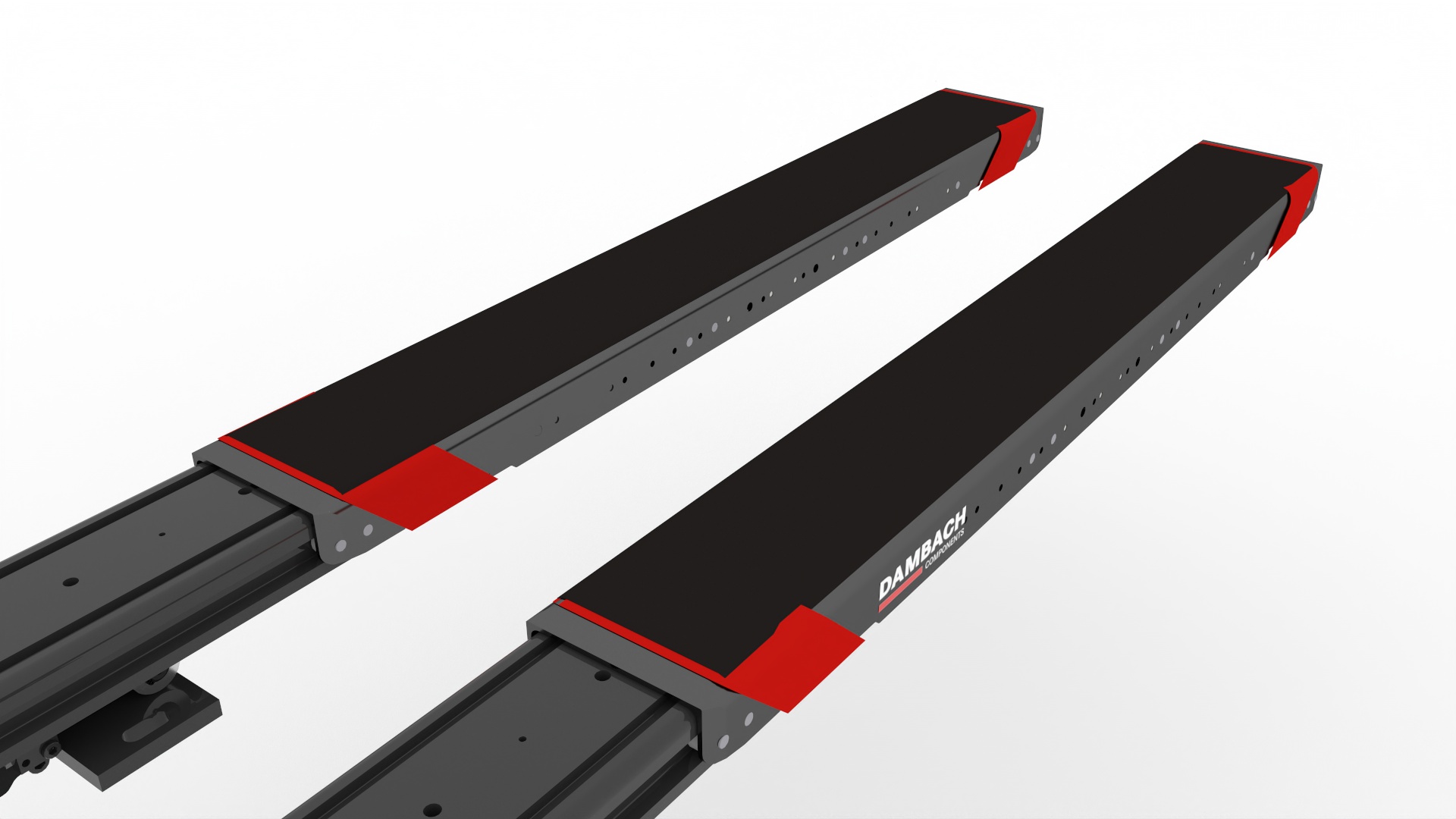

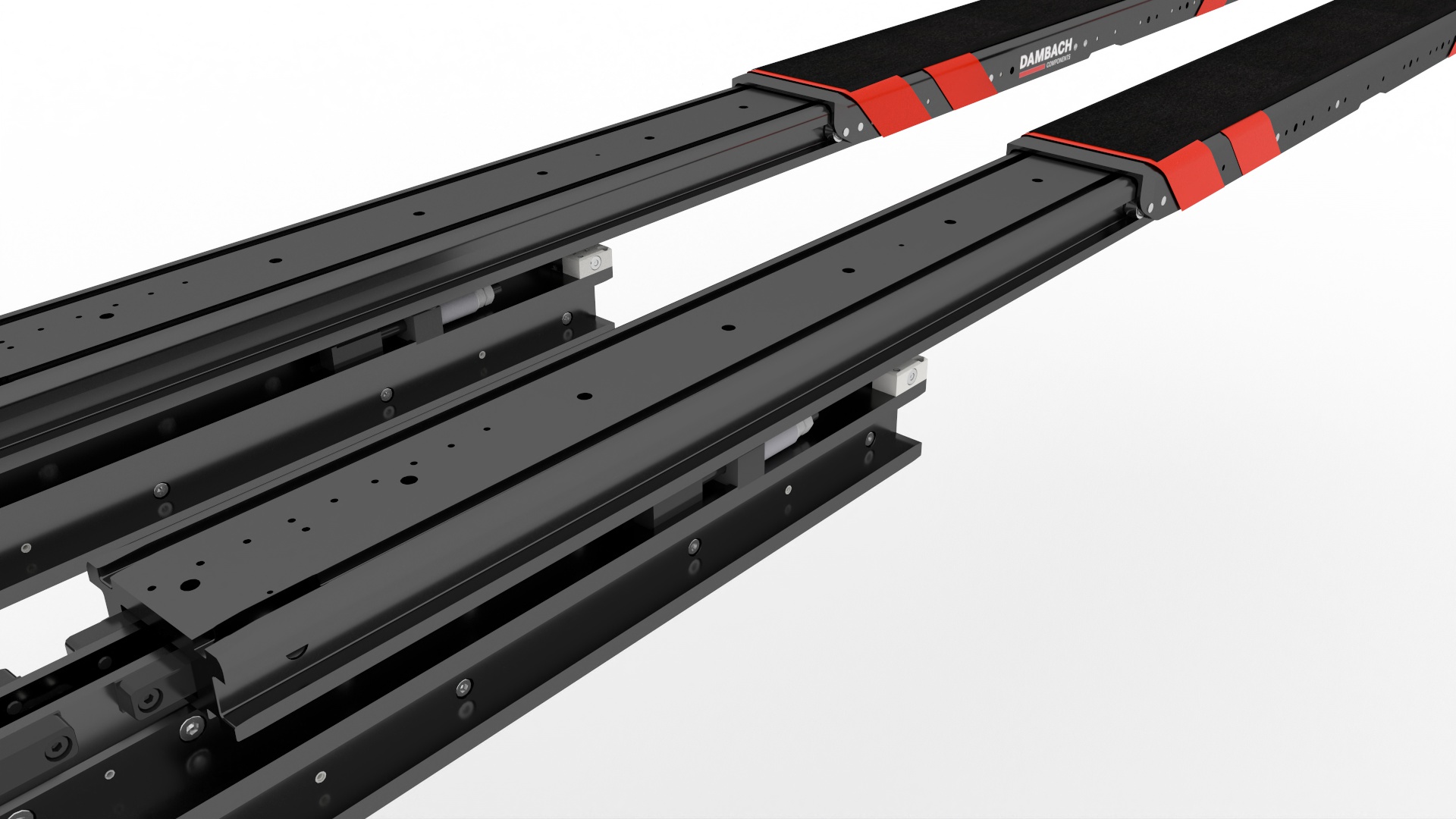

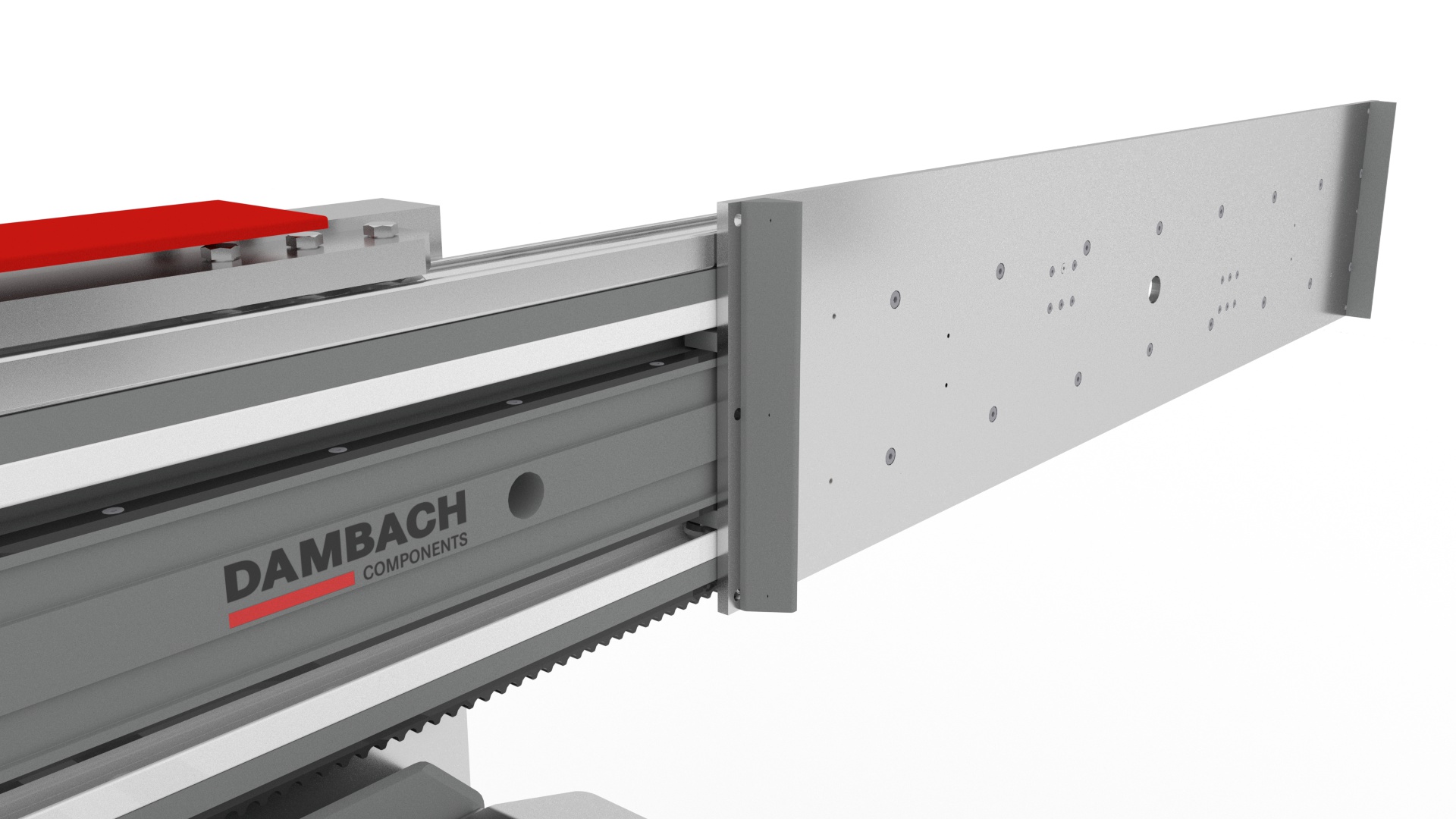

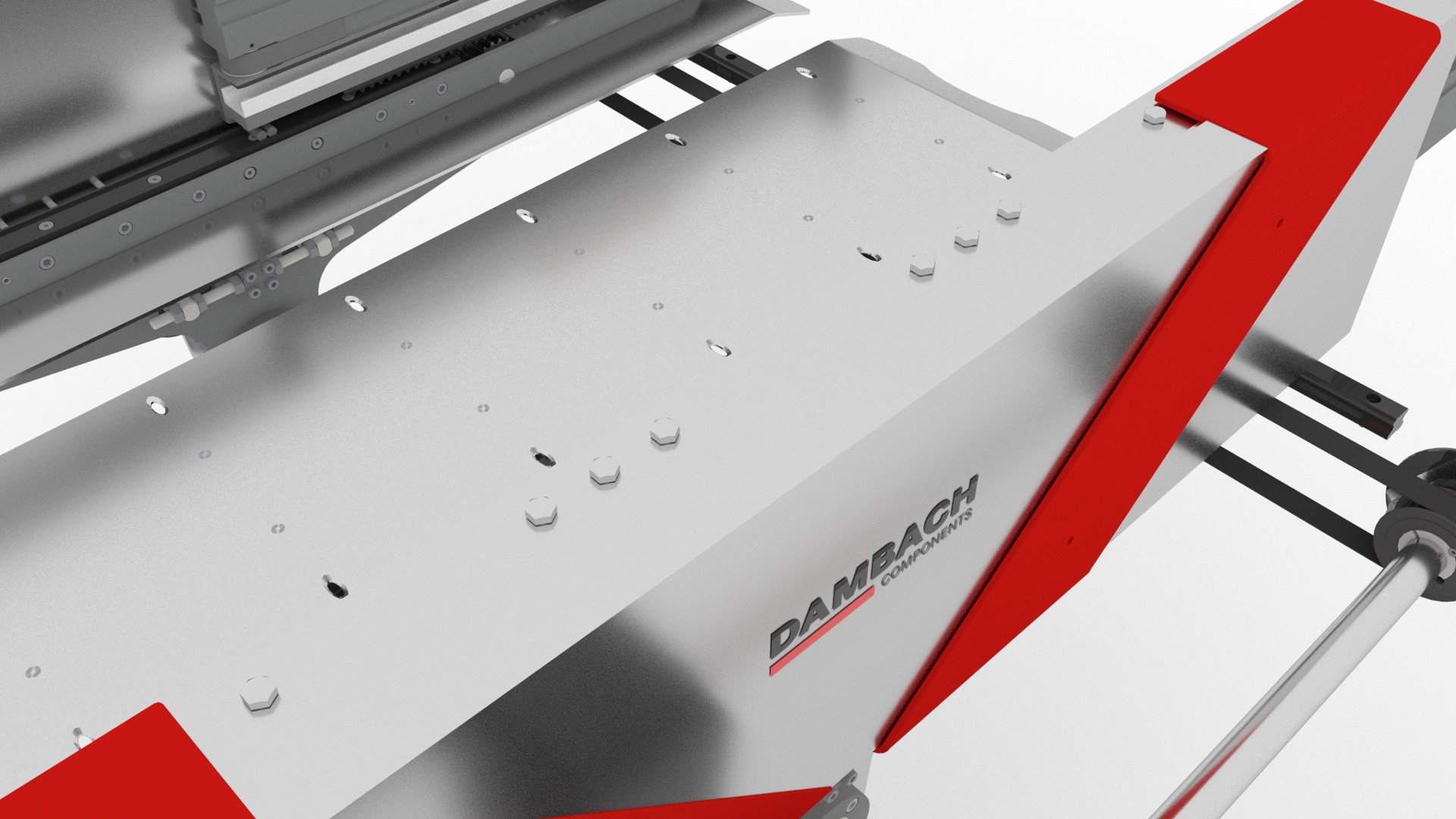

Telescopic Fork Single Deep for Large Load Carriers

DAMBACH Telescopic Forks for the single depth storage of pallets, barred boxes, trolleys, and more stand out for the extraordinary quality of their materials and manufacturing. This means they offer long-lived functional reliability, support high availability, and provide efficiency.

All DAMBACH Telescopic Forks can be used flexibly and are secure when carrying their load. The flexible mounting plates mean that there are broad areas of application for the telescope – whether with conveyor technology, a single-bar lifting beam, a lifting frame, or a transport car. The optimized contact surface of the upper tables ensure security during carriage, reduced pallet wear, and precise positioning of the load carriers.

Loads of up to 1,500 kg with a simultaneously large storage depth are not a problem for the robust design. In particular, the DAMBACH single deep telescopes

release their full potential when combined with multiple individual tines, and can even handle special load carriers.

Technical Data

Payload: Up to 1.500 kg

Temperature: -30 °C to +40 °C

Speed: Up to 120 m/min

Acceleration: Up to 5 m/s²

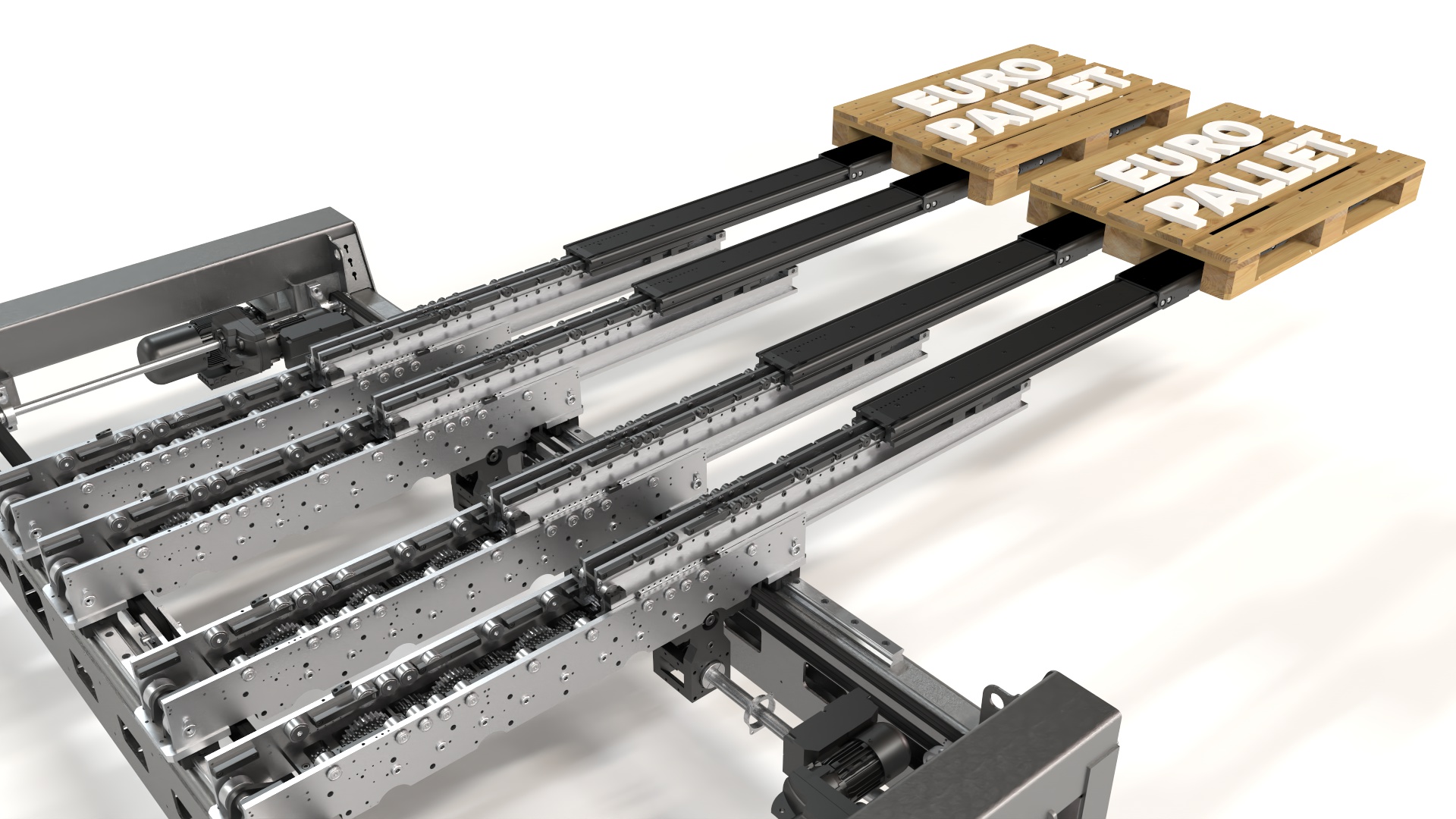

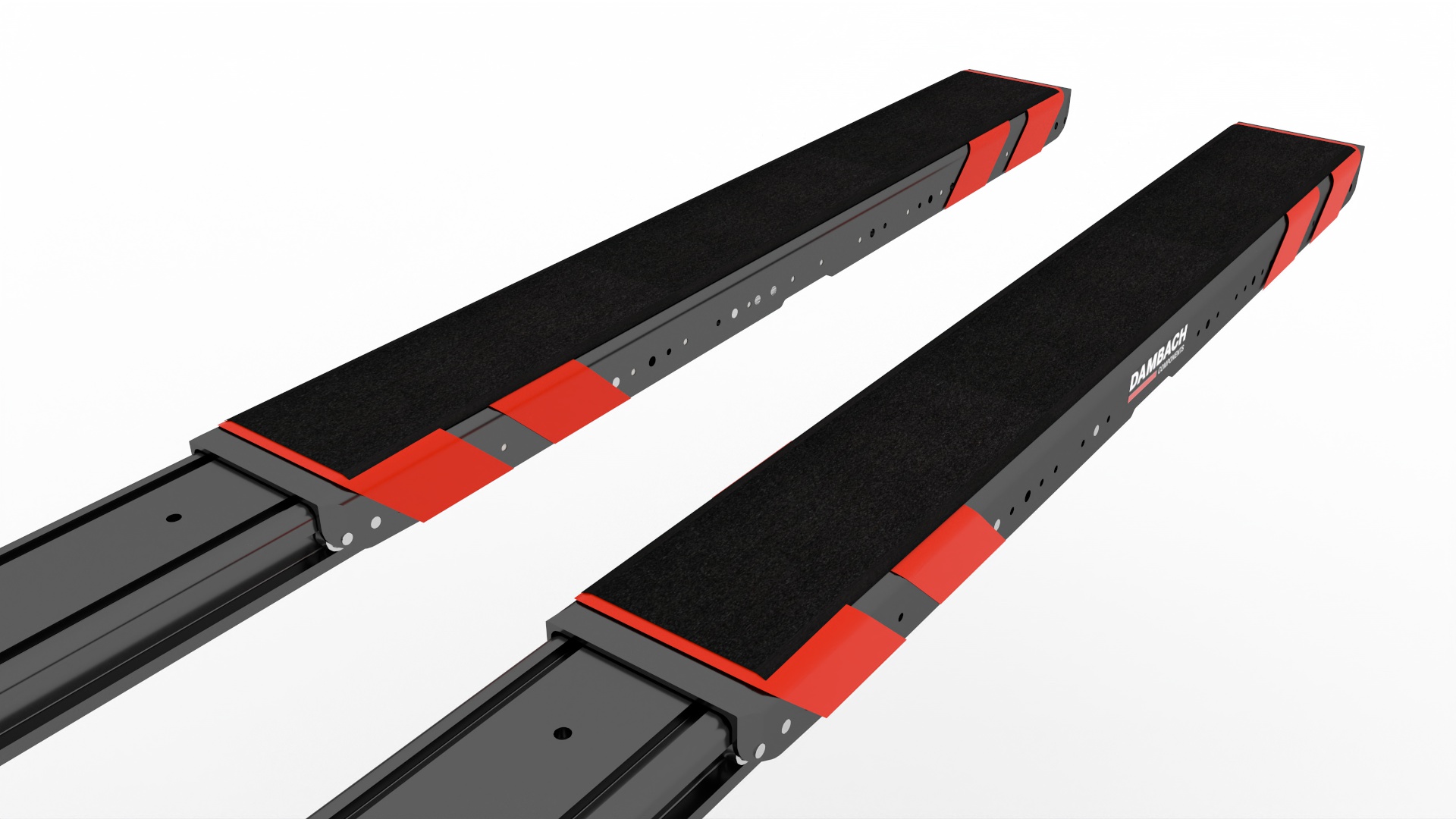

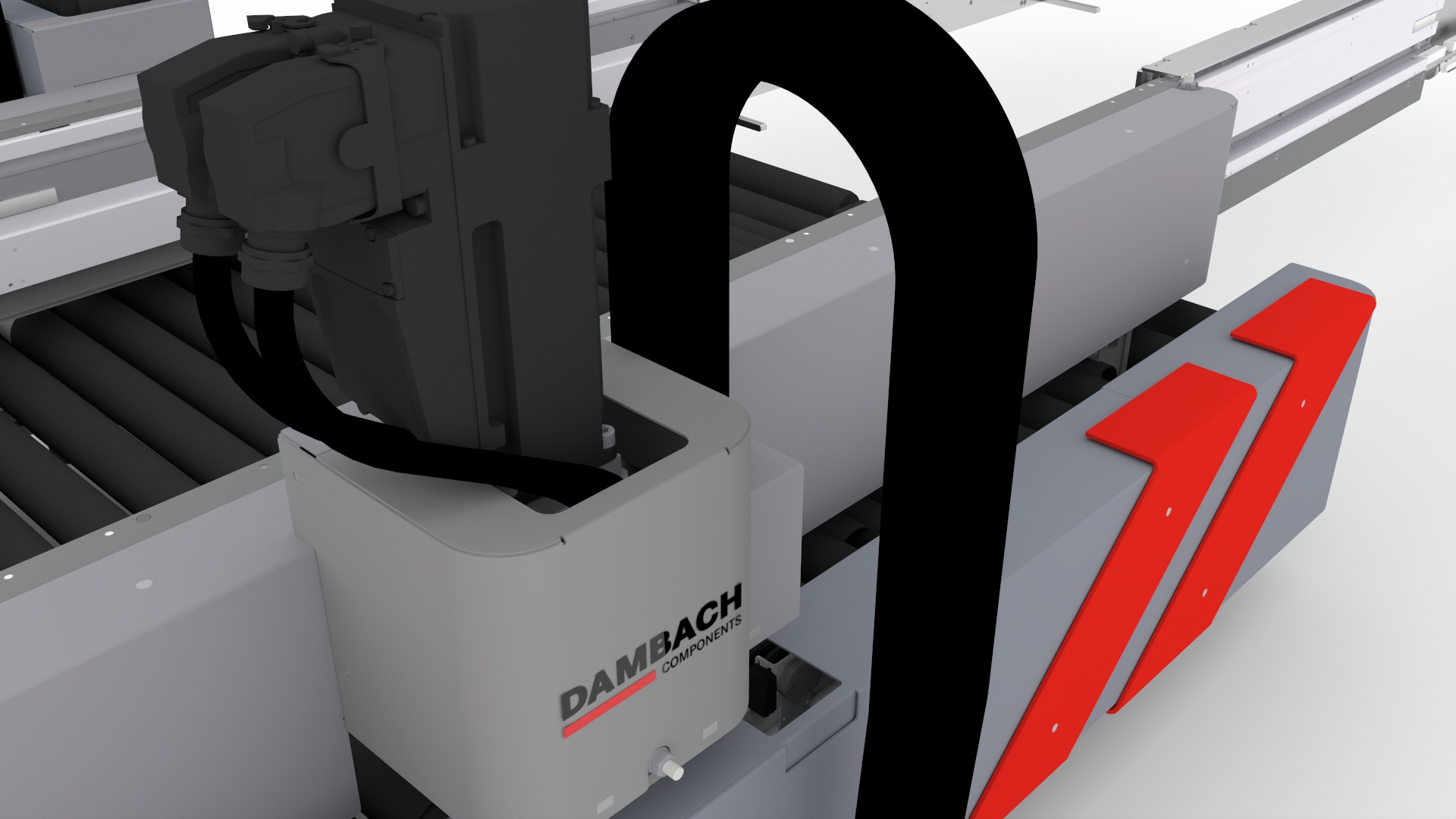

Telescopic Fork Double Deep for Large Load Carriers

DAMBACH Telescopic Forks for the double depth storage of pallets, barred boxes, trolleys, and more stand out for their particularly high-grade materials and excellent functionality. The Telescopic Fork, Double Deep, is available with one or two drive systems – which means the telescopic extensions can also be driven individually for even more flexibility in storage.

With the DAMBACH Telescopic Fork, manufacturers of storage and conveyor systems can find a component that offers them more degrees of freedom and allows

simplified control sequences. This enables tine geometries tailored to their requirements for small open spaces and approach dimensions.

If energy consumption needs to be prioritized or mast vibration reduced, DAMBACH and its lightweight designs made of high-strength aluminum off er the right answer. A full solution is also offered for variability, with the standardized telescopic kit providing telescopes for almost any requirements.

The double deep telescope is of course also perfectly equipped for use in deep-freeze situations.

Technical Data

Payload: Up to 1.500 kg

Temperature: -30 °C up to +40 °C

Speed: Up to 120 m/min

Acceleration: Up to 5 m/s²

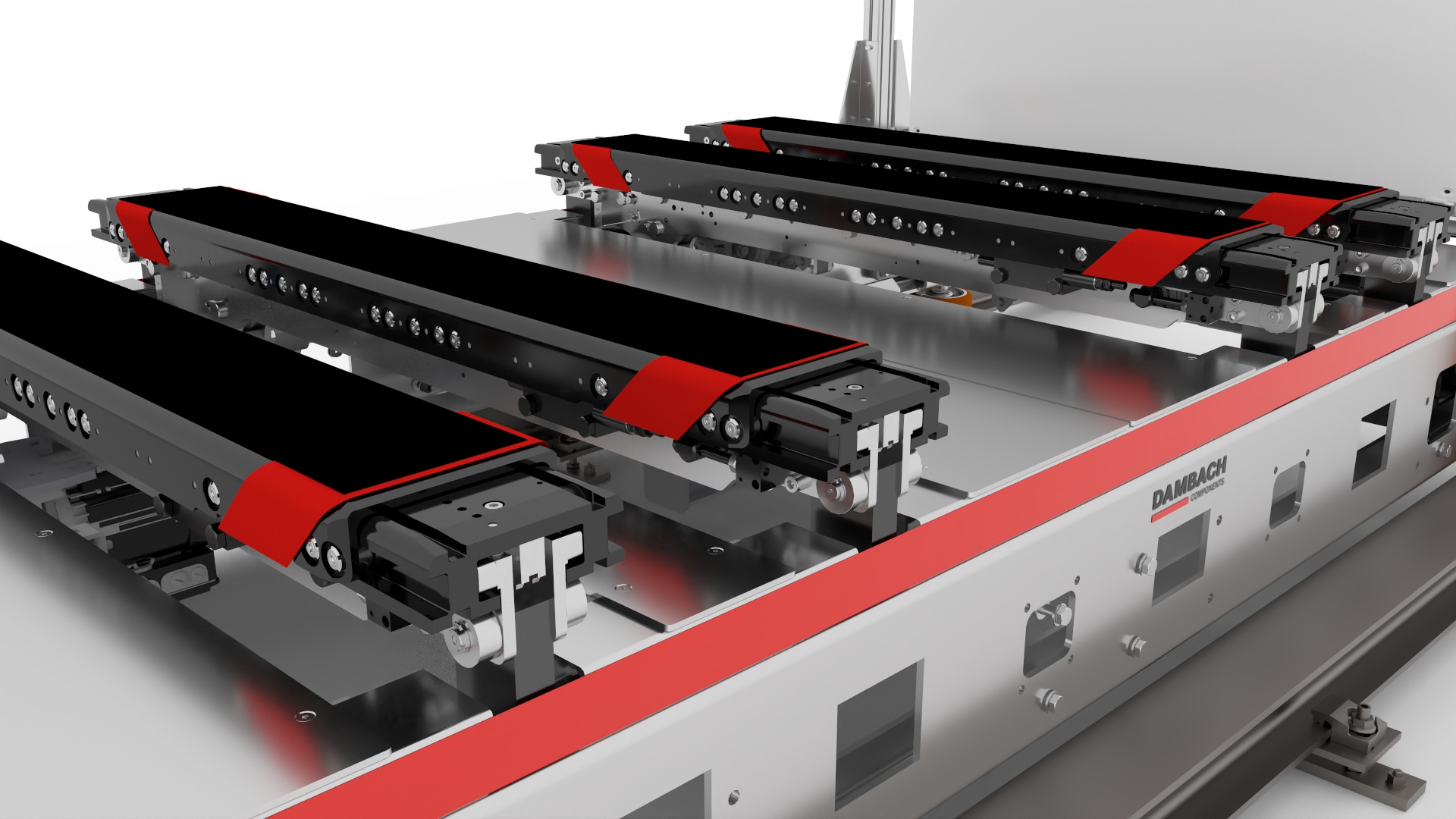

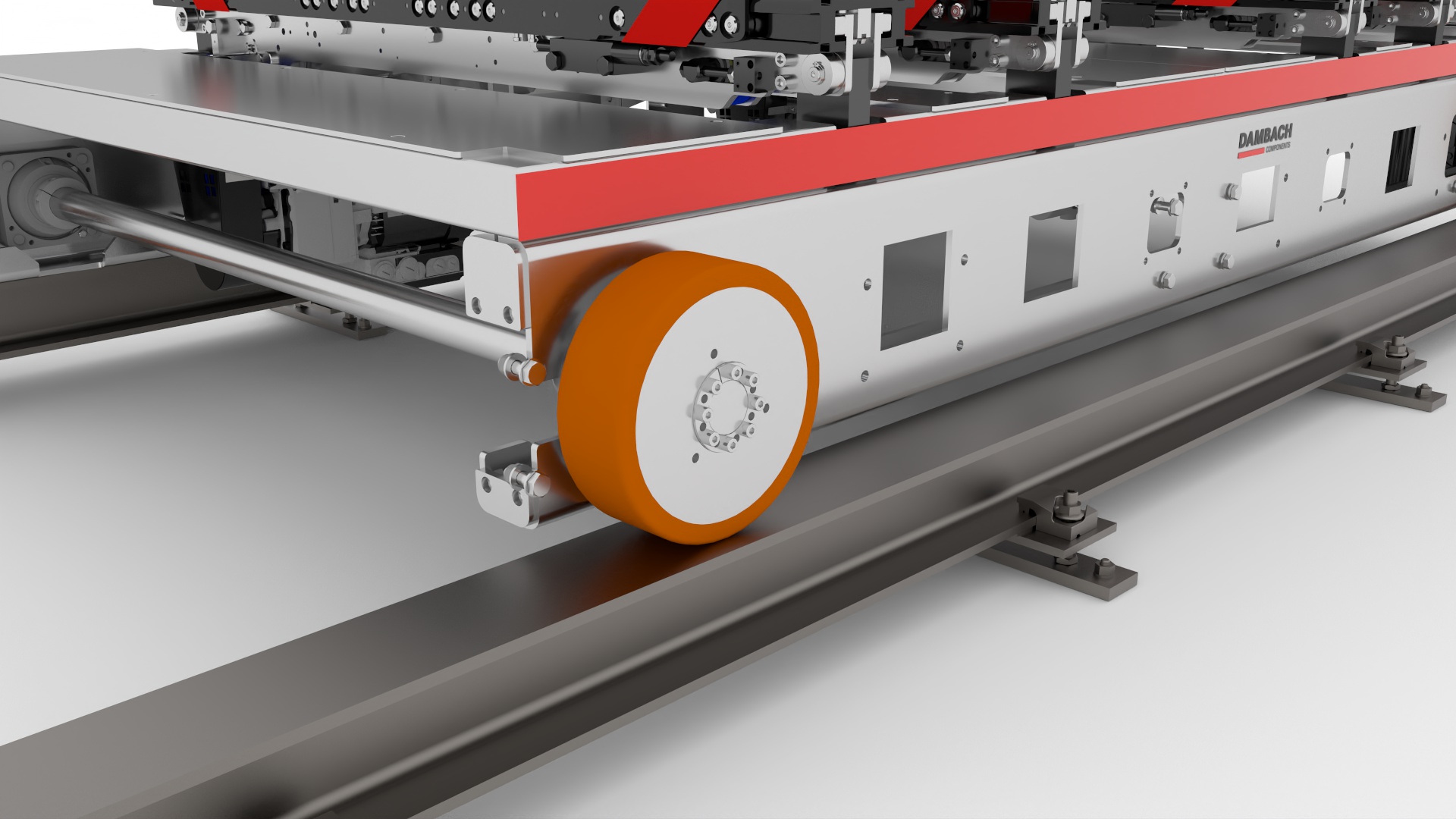

Box Grabber for Small Load Carriers

The DAMBACH Box Grabber is the versatile solution for boxes of diff erent sizes. Up to five gripper fingers enable rapid entry into and removal from storage up

to four boxes deep.

Coated motor rollers and adjustable side bolsters provide secure support for four loads simultaneously, including ones of diff erent sizes. Combined with a load capacity of up to 100 kg, the DAMBACH Box Grabber is a multitalented tool for versatile use.

Lightweight construction and integrated drive systems make for a compact, space-saving design which benefits manufacturers of automated small-parts stores as well as warehouse operators.

Its unconditional deep-freeze layout is just further reason why the Box Grabber is perfect for universal use.

Technical Data

Payload: Up to 100 kg

Temperature: -30 °C up to +40 °C

Speed: Up to 120 m/min

Acceleration: Up to 6 m/s²

Clamping Gripper for Small Load Carriers

The DAMBACH Clamping Gripper is ideal for the fast and secure handling of boxes and cartons in single-deep storage. Thanks to the tine lifters, the robust system

adapts to various container and box dimensions, offering maximum efficiency with extreme flexibility.

Even heavy small-load carriers can be put into and taken out of storage securely and reliably – making the options for using the load-handling device go significantly beyond the normal small parts.

Whether a deep-freeze warehouse or the toughest spot in production, the DAMBACH Clamping Gripper works with precision and perfection. What’s more, it is one of the most efficient load-handling devices for sophisticated small-load carriers.

Technical Data

Payload: Up to 50 kg

Temperature: -30 °C up to +40 °C

Speed: Up to 120 m/min

Acceleration: Up to 6 m/s²

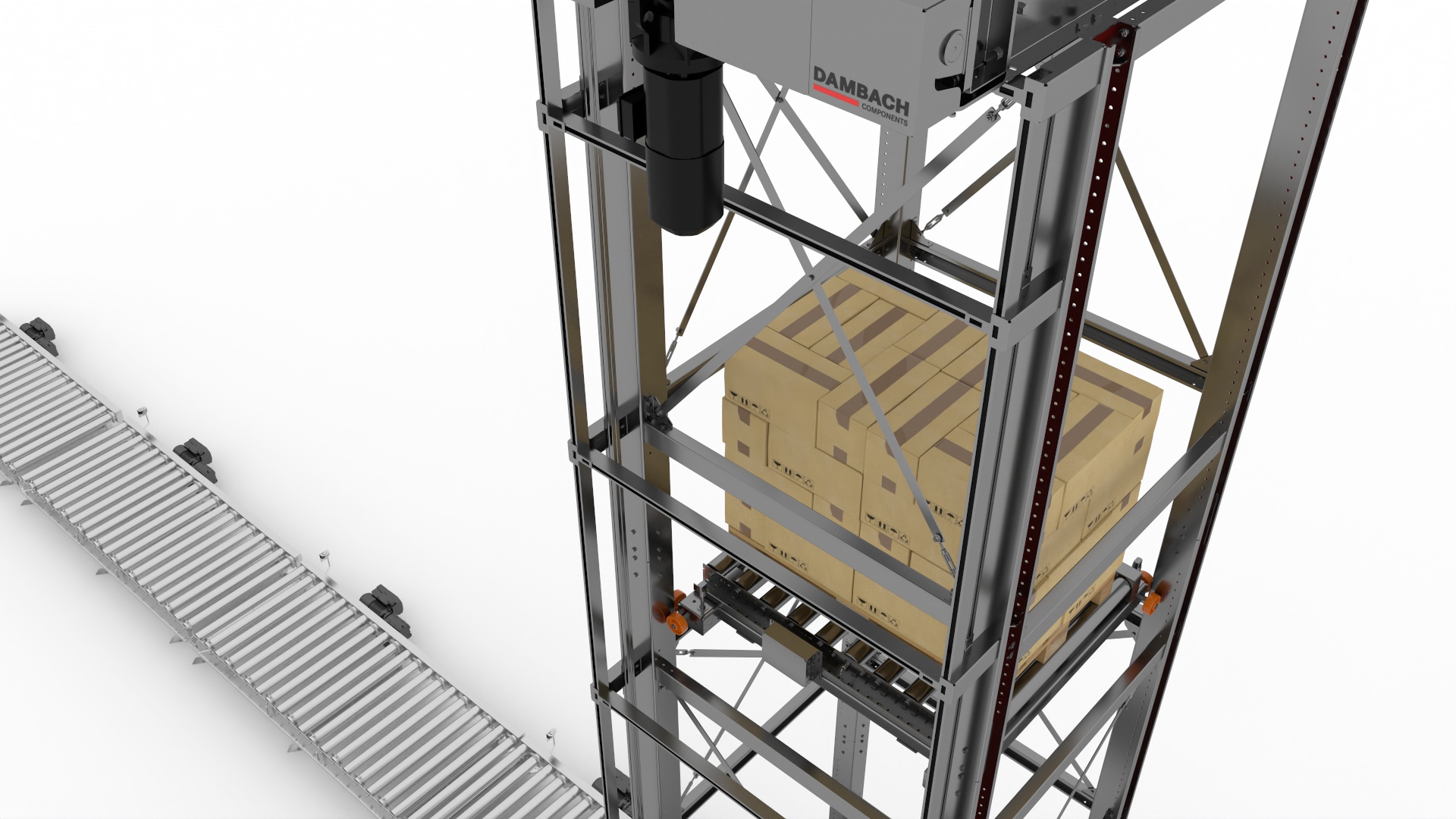

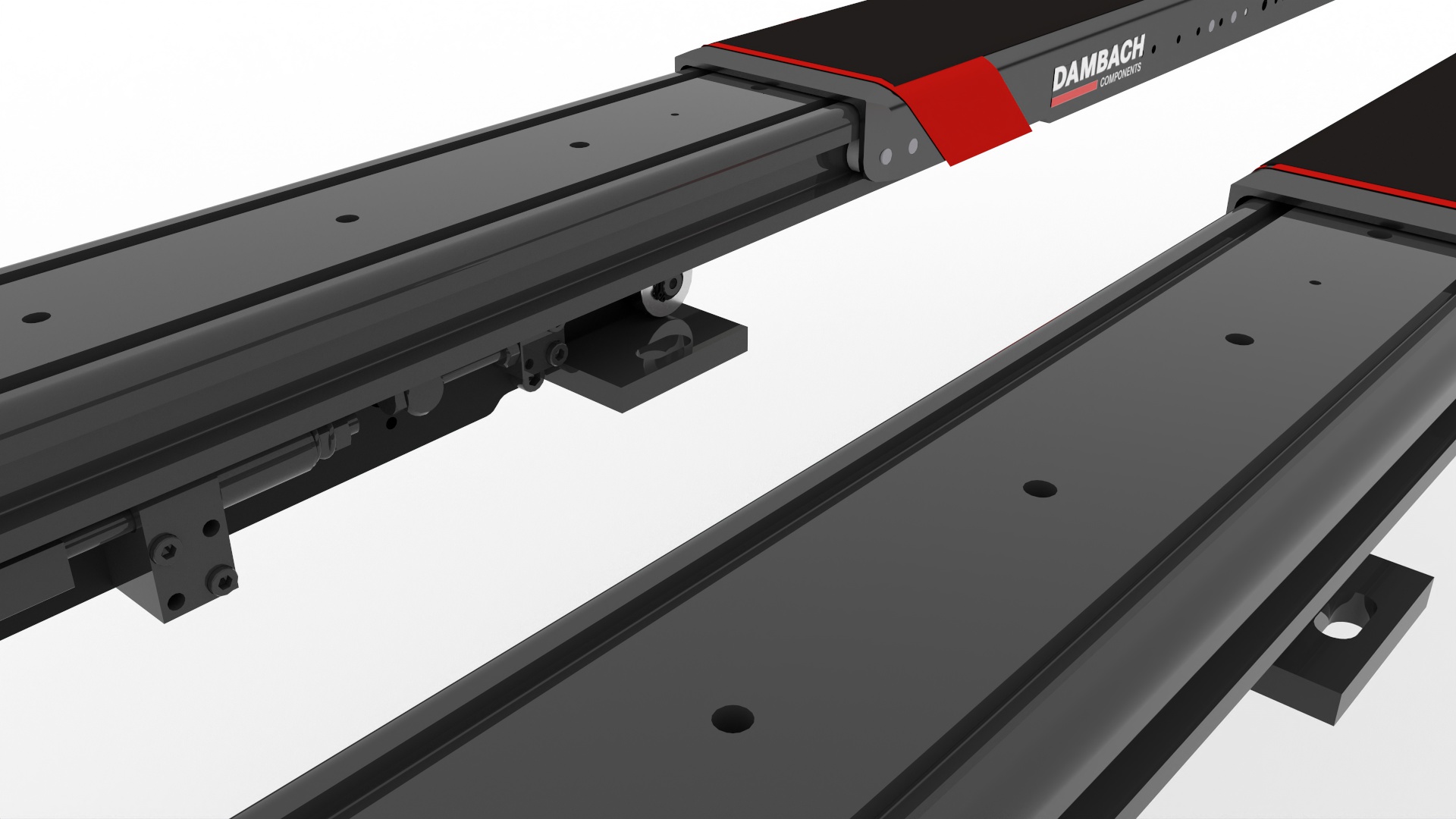

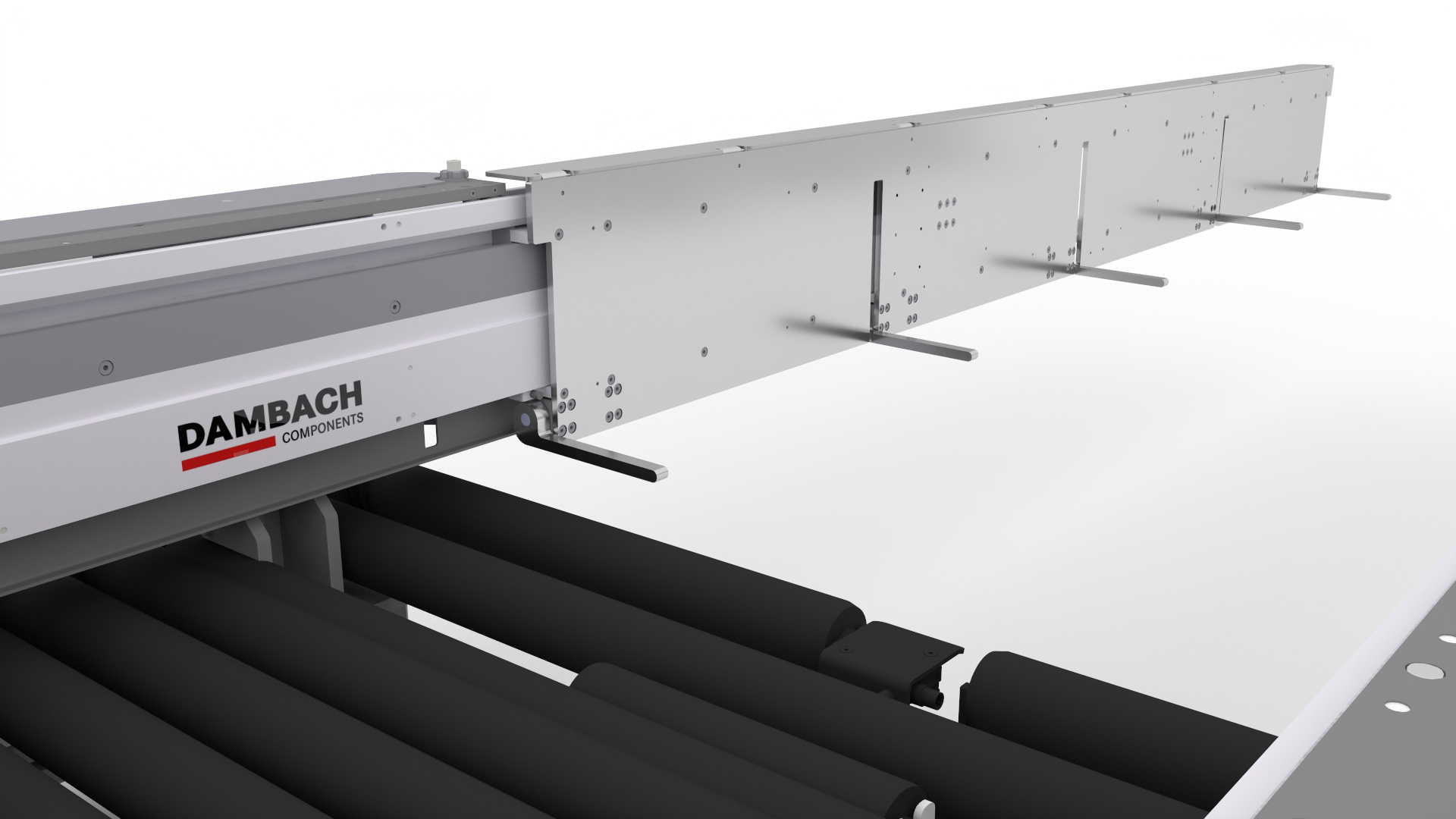

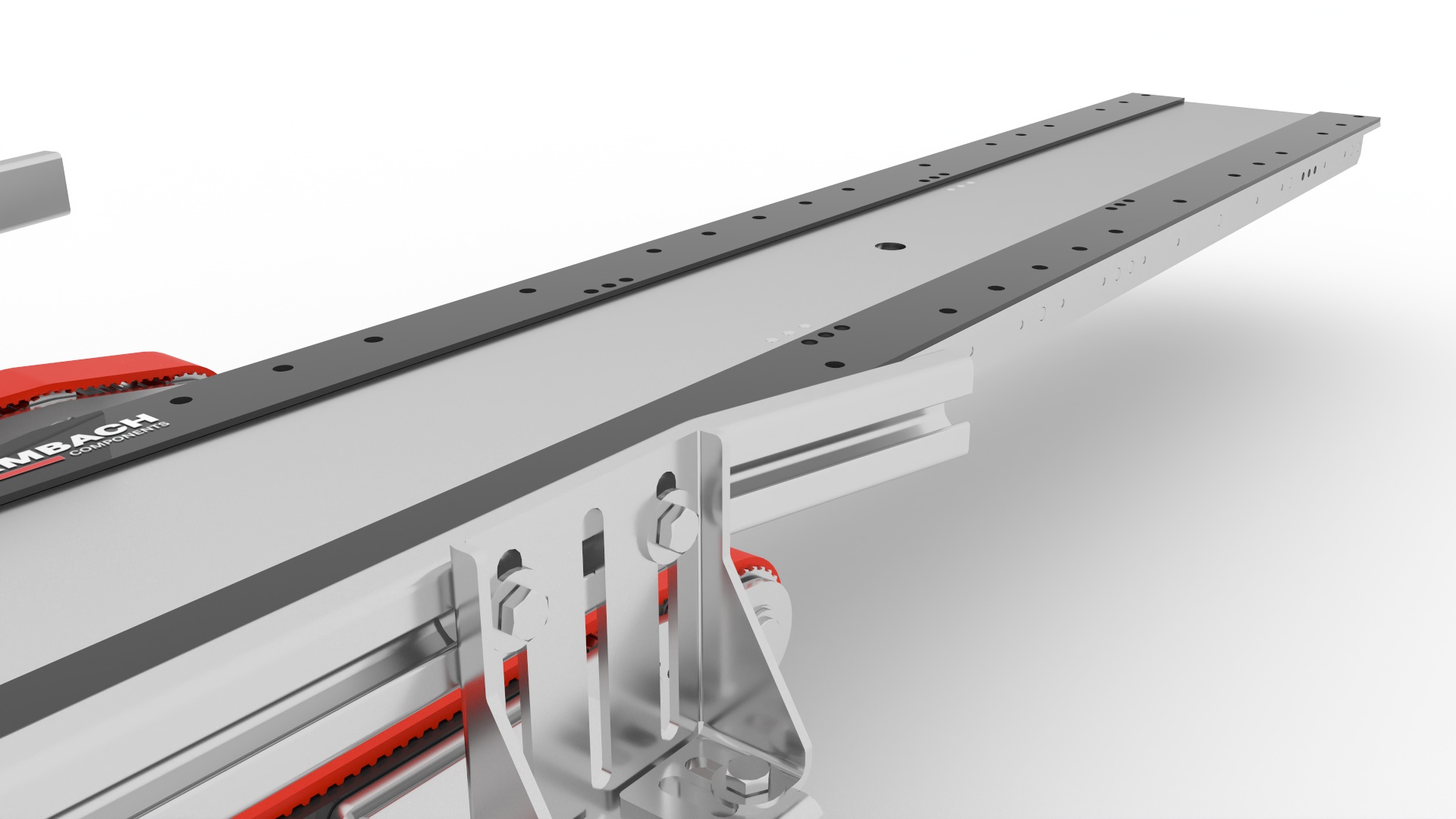

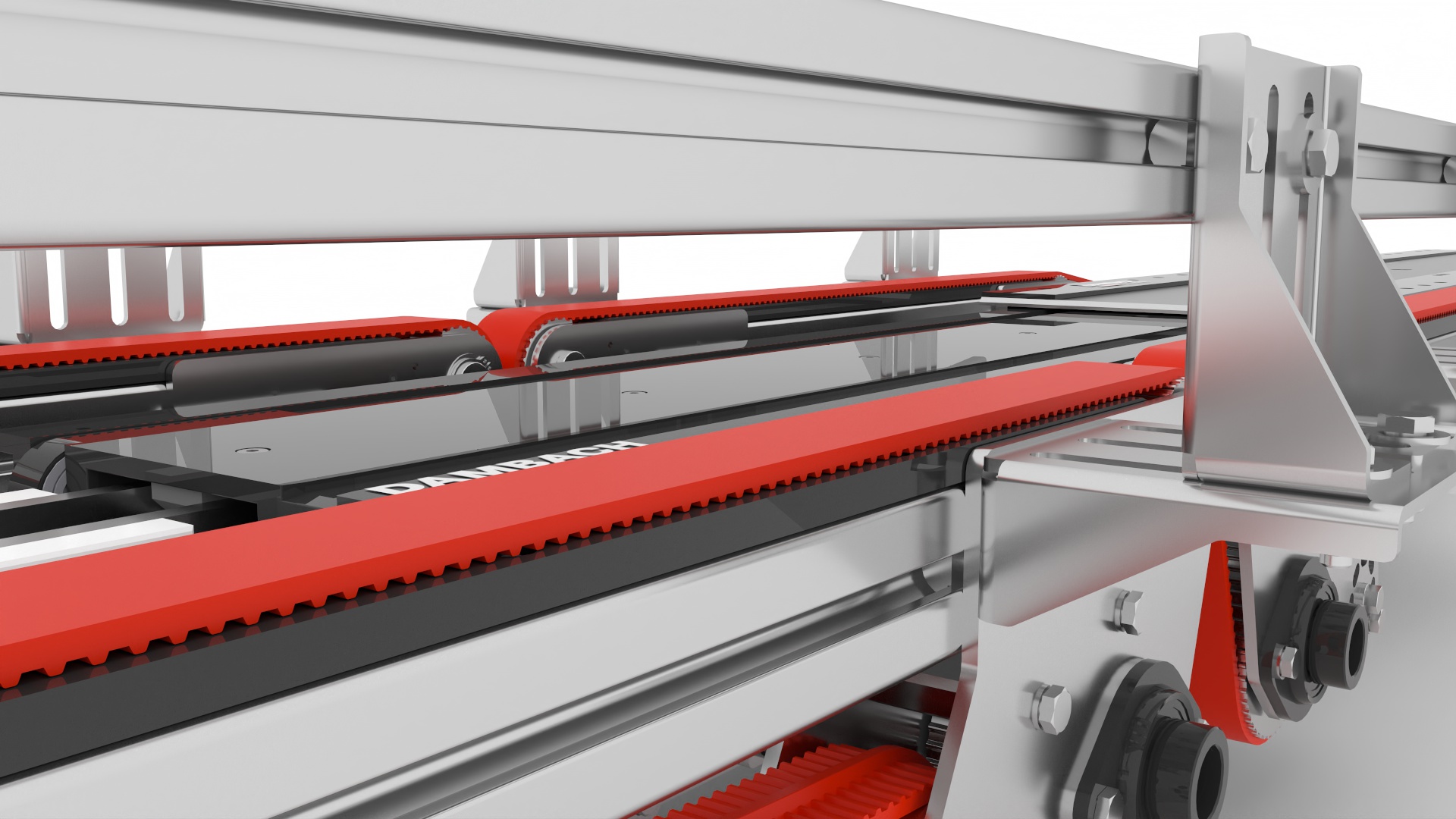

Miniload Telescopic Table for Small Load Carriers

The DAMBACH Miniload Telescopic Table is a first-class choice for ultradynamic entry into and removal from storage for small-part containers in one-or-more-deep storage.

Long extendable lengths and load capacities of up to 100 kg make for maximum flexibility while demanding little energy. The load-handling device was designed to save weight yet still impress with high rigidity and durability.

Precision lies at the heart of this device. The perfectly coordinated drive concepts of belt conveyors and telescopic unit move the load gently and precisely and the

centering unit positions it optimally, even in tight spaces/conditions.

The system’s further strengths include optimal approach dimensions, an adaptable upper table with nonslip lining for different load carriers, and integration with various control concepts.

The DAMBACH Miniload Telescopic Table does its job of moving loads onto small-part conveyor technology heroically, even in the toughest deep-freeze conditions. The centering unit is the perfect addition to make this load-handling device a veritable all-rounder.

Technical Data

Payload: Up to 100 kg

Temperature: -30 °C to +40 °C

Speed: Up to 90 m/min

Acceleration: Up to 4 m/s²

Do you have any questions, suggestions or would you like more information about our products?

Write us via the contact form and we will contact you as soon as possible.